The standardisation study facilitates the inclusion of wood from resin tapped pines in the Spanish standard UNE 56544 (Visual classification of sawn wood for structural use. Coniferous wood), in order to favour its use and marketing as structural wood.

Simultaneously, the study compares the physical-mechanical properties of resinated Pinus pinaster wood against non-resin wood under the same normative parameters (UNE 56544), so that the technical buyer can evaluate which product is the most suitable for the intended application.

Structural use is one of the main markets for sawn timber in Europe. The fact that the standardisation and mechanical characterisation of the main coniferous species has not taken into account resin tapped pines means a disadvantage for its marketing.

When analysing the potential uses of the forest and its compatibility, forest managers may have doubts when managing stands towards resination if this implies excluding the possibility of using the wood in the structural timber market.

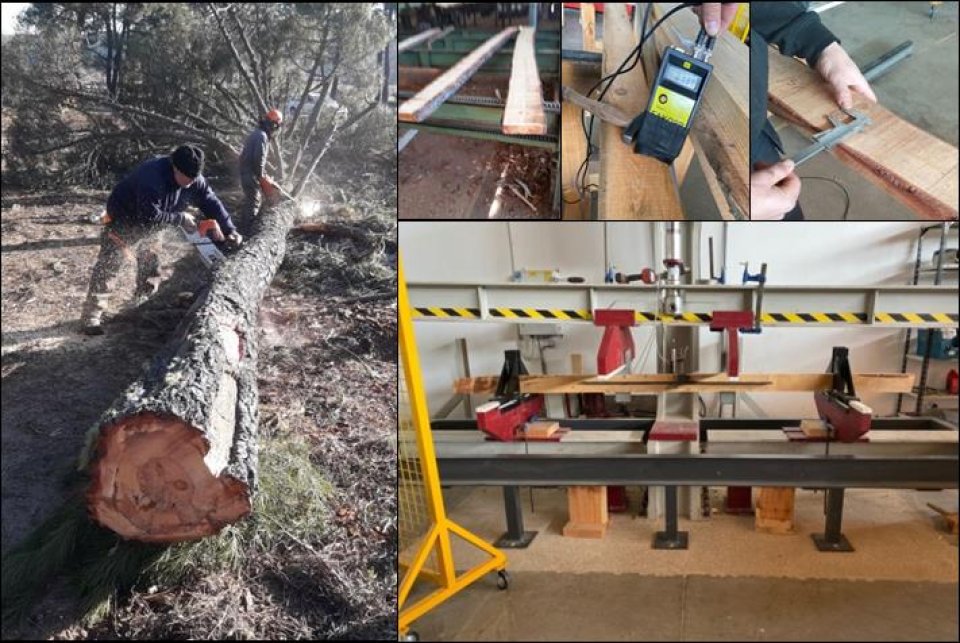

The results of the visual classification analysis for structural use (UNE 56544) of 50 boards of dimensions 50x120x3000mm of Pinus pinaster Ait. subsp. mesogeensis resinated at least 25 years, were:

Visual class ME-1 (good) : 41,9 %

Visual class ME-2 (suitable): 47,3 %.

Rejections (not allowed): 9,6%.

The characteristic values of the resinated pine are in normal ranges of resistance and rigidity for the wood of Pinus pinaster in Spain, and they do not suppose reduction against non-resined pines.

The density of the resined wood is 17% higher than the one coming from non-resinned pines.

The density of the wood is taken into account in the structural calculation according to Eurocode 5 in the design of joints using metal connectors so that a higher density of the wood means a better joint strength at the same level of the other parameters included in the Johanssen equations.

Forest managers should consider resin use in Pinus pinaster forests as a complementary use that does not devalue the quality of the wood in terms of its further structural use.

The volume of Pinus pinaster resin wood is very small compared to non-resin wood. The supply capacity of this material depends directly on the resination activity, so it may not be easy to ensure the obtention of this product.

Some sawmills report a decrease in sawing yield due to resin clogging of the saws. This problem can be solved by properly lubricating the blades.

Resined wood has a good reputation for its durability due to its natural protection against xylophages. However, there is currently no scientific or technical evidence to support these qualities.

To enhance the value of resinated wood for structural and other uses, it would be necessary to carry out the standardised tests regarding durability against xylophagous fungi (EN 351-1 and 351-2), termites (EN 117 and 118) and Hylotrupes bajulus (46-1 and 46-2).

José Luis Villanueva, joseluis.villanueva@cesefor.com, http://www.cesefor.com/

Javier Calvo-Simón, javier.calvo@cesefor.com, http://www.cesefor.com/

Further information

Cesefor Foundation, 2019

Mechanical testing, edgewise bending strength according to UNE-EN 408:2011+A1:2012. Cesefor Foundation, 2019